An Introduction to laser mirror

Table of Contents

1. What is a laser mirror?

2. What is a laser?

3. Types of lasers

4. Fields and applications of lasers

4-1. Manufacturing

4-2. Medical applications

4-3. Communications

5. Laser mirror structure

5-1. Reflective layer

5-2. Substrate

Related product pages

1. What is a laser mirror?

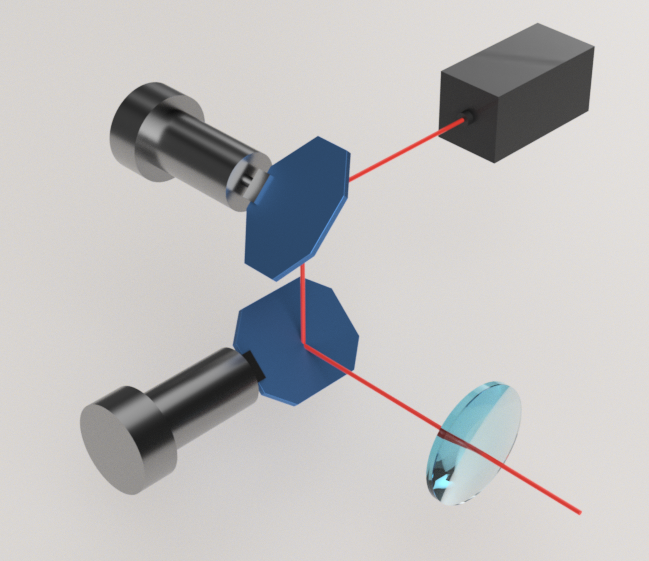

A laser mirror is a special mirror designed to reflect laser light.

It is characterised by its high reflectivity and durability (heat resistance) against lasers. This allows for maximum utilisation of laser light energy. Laser mirrors are used for various purposes in laser devices and optical systems, but their main use is to focus or propagate laser light in the form of a beam.

Laser light emitted from a laser device is reflected by the mirror, allowing the beam to be directed in any desired direction. Laser light is generated at a specific wavelength with high power, making it highly susceptible to thermal damage when using conventional mirrors.

Laser mirrors are manufactured with special coating designs and materials that provide extremely high reflectivity for specific wavelengths and output levels while minimising thermal damage.

2. What is a laser?

A laser is an acronym for Light Amplification by Stimulated Emission of Radiation (LASER).

Its characteristics are that it is highly directional, coherent, and monochromatic. Directionality refers to the fact that the intensity of light or sound varies depending on the direction, and highly directional waves have uniform intensity in one direction. Coherence refers to the ability of waves to interfere with each other, meaning that the peaks and troughs of the waves are aligned. Monochromaticity refers to the fact that the wavelength range of laser light is extremely narrow within a certain range of wavelengths.

3. Types of lasers

There are four types of lasers, classified by the type of medium used.

(1) Solid-state lasers Example: YAG laser

(2) Liquid lasers Example: Organic dye laser

(3) Gas lasers Example: CO₂ laser

(4) Semiconductor lasers

4. Fields and applications of lasers

4-1. Manufacturing

Laser mirrors are used in processing such as cutting and marking. They are also used in welding applications. In such cases, laser mirrors enable the laser to be used with high positioning accuracy.

4-2. Medical applications

Laser mirrors are also widely used in the medical field. In laser surgery, mirrors can be used to guide the laser beam into the patient’s body.

In skin treatment, when treating skin lesions or unnecessary tissue, using a laser mirror enables precise irradiation of the laser beam. In ophthalmic surgery, systems incorporating laser mirrors have made it possible to use lasers in eye surgery.

Laser mirrors are essential for effectively and safely using laser light due to their high reflectivity and heat resistance.

4-3. Communications

Laser mirrors are also extremely important components in the field of optical communications. Optical fibres are used for high-speed data transmission, and mirrors are used at the ends or branching points of optical fibres to precisely control light signals.

Additionally, in optical communication networks, mirrors are used for optical switching, making them indispensable components for signal transmission and control.

5. Laser Mirror Structure

Laser mirrors are made up of a substrate (mainly glass) and a reflective layer (mainly metal or dielectric multilayer film).

5-1. Reflective Layer

The reflective layer is constructed on the substrate to reflect the laser beam. Generally, materials with high reflectivity, such as metals, are used. However, in cases where high thermal durability is required, dielectric materials are used. When using dielectric materials, factors such as reflectivity, the wavelength to be used, and the wavelength to be blocked are considered, and the number of layers and the thickness of each layer are controlled at the nanometre level during film deposition.

5-2. Substrate

The substrate serves to support the reflective layer. Generally, rigid materials such as glass or metal are used. However, to enhance the precision of the laser system, flatness and heat resistance are critical. Therefore, substrates used in laser mirrors are of high quality and correspondingly expensive.